精品推荐 | MC13X系列引线框架AOI 检测设备

2024-04-07 10:24

适用于引线框架在生产、加工过程中的各种不可避免地缺陷检测。例如:错冲、漏冲、脏污、氧化、毛刺、压伤、变形、屑痕等能有效提升产品合格率,降低生产成本,缩短开发周期。

深入剖析

In depth analysis

精准光测,高效无忧

针对行业内凹痕检测痛点,采用领先的光学方案和多通道检测算法,有效避免设备抖动对检测结果的影响,真正做到高速高精度和低误报率检测,高精度、高速度、兼容性高,操作简单。

In response to the pain points of indentation detection in the industry, we adopt leading optical solutions and multi-channel detection algorithms to effectively avoid the impact of equipment shaking on the detection results, truly achieving high-speed, high-precision and low false alarm rate detection, high precision, high speed, high compatibility, and simple operation.

高速检测,一键建模

选用高速工业相机,加以突出的光学方案,组合成一套高速检测设备,软件界面简洁、一键建模、操作简单、精度高、运行稳定可靠的特点。

The high-speed industrial camera is selected, combined with prominent optical solutions to form a set of high-speed detection equipment. The software interface is simple, one click modeling, simple operation, high accuracy, and stable and reliable operation are the characteristics.

防抖算法,稳控生产

软件算法具有防抖动功能,避免生产过程中产品抖动引起的误判。

The software algorithm has anti shake function to avoid misjudgment caused by product shake during the production process.

自校自调,智能无忧

设备自动运行过程中,具有自动校孔功能,便于生产调试,降低设备使用与维护人员的要求。

During the automatic operation of the equipment, it has an automatic hole calibration function, which facilitates production debugging and reduces the requirements for equipment debugging personnel.

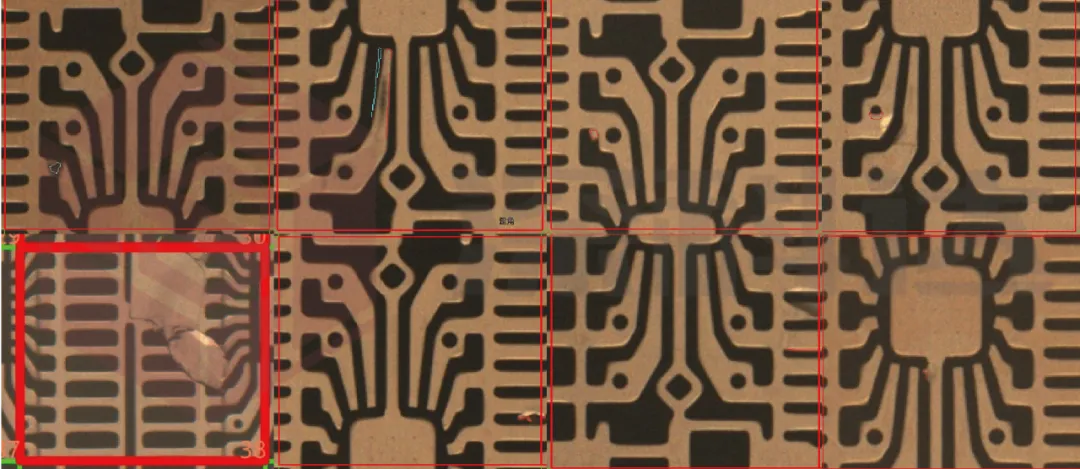

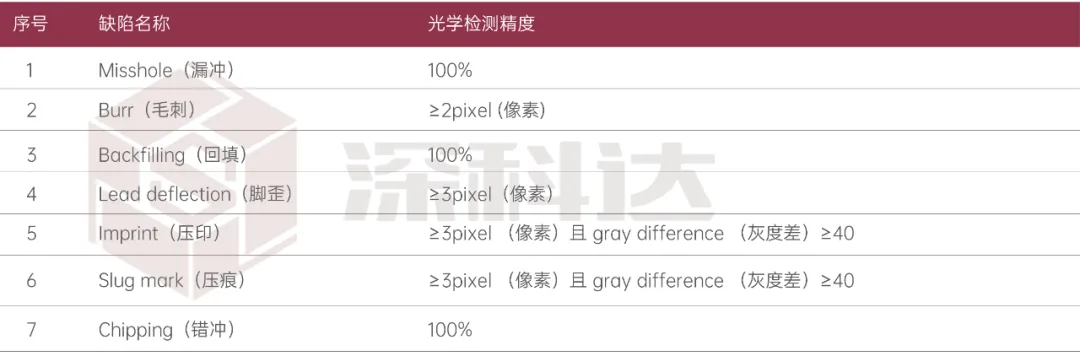

检测项(部分)展示

Display of detection items (partial)

检测功能

Detection function

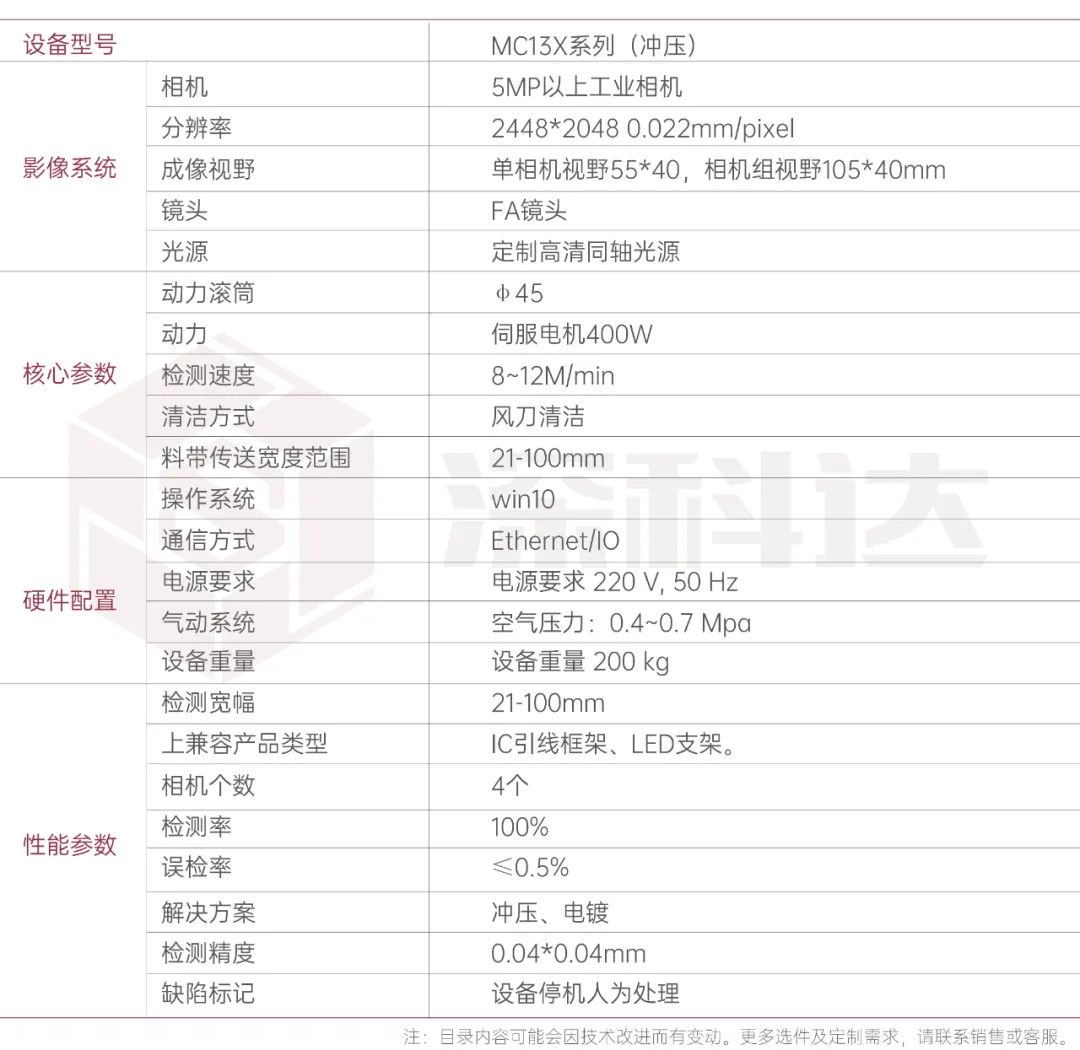

参数规格

Parameter specifications

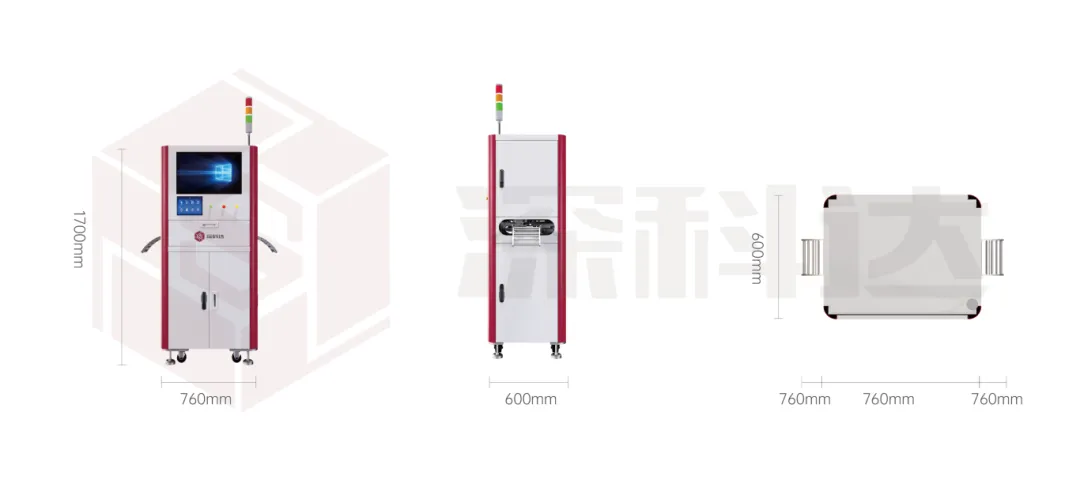

设备尺寸

Equipment size

相关新闻